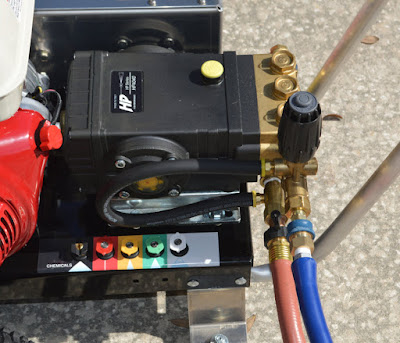

Water Cannon has repair parts and kits to fix

your pump. In so many cases we find or should I say cannot find the label

that has the model number on the pump as shown in this picture. Of course

this is critical to ensure we send you the correct parts to fix your pump problem. A Picture like this is worth a thousand words.

Sometimes we can identify the pump even without the head or manifold

removed as shown. This can be a little like the crime dramas you see on

TV. I call it: PSI. Pump Scene Investigation. I can

tell by the picture that is a belt drive. I can see by the crankcase

of the pump and shape of the manifold that this is a General Brand Pump.

To identify the pumps actual model number, with the manifold already removed,

you can measure the outside diameter of the white ceramic Plunger or

piston in millimeters. That will give us the bore of the pump piston.

To measure the stroke or how far back and forth that same piston travels, hold

a ruler next to the piston as you turn the crankshaft of the pump and

then see how many millimeters in one direction the piston travels.

If the label is missing from your pump, all of this information combined will

ensure the correct pump identification. Call Water Cannon to

order the correct parts to get you back up and running, right the first

time.

In looking at the pump that we just talked about above, your

eagle eye may have picked up the crack running down the length of the piston.

This crack is caused most often by what is known as “Thermal Shock”.

Thermal Shock is what happens to a piston or plunger when it sees a drastic

temperature change usually from hot to cold. The most common

example is when a pressure washer is started before the water is turned

on. The friction from the dry plunger against the seals can heat up

in seconds. It may be too late before the operator realizes that there is

no water to the pump. By the time the user gets the water

turned on, the plungers are hot. When the cold water is

introduced, this shocks the ceramic and a crack is formed. This

will cause the seals to fail and leak water back into the

crankcase. If left undetected, catastrophic damage can occur such as thrown

connecting rods due to poor lubrication. The moral of the

story: Always have water flowing through the pump before start up.

Written by Jim Grode

.gif)

.gif)

.gif)